Thermal Management

Thermal

Management

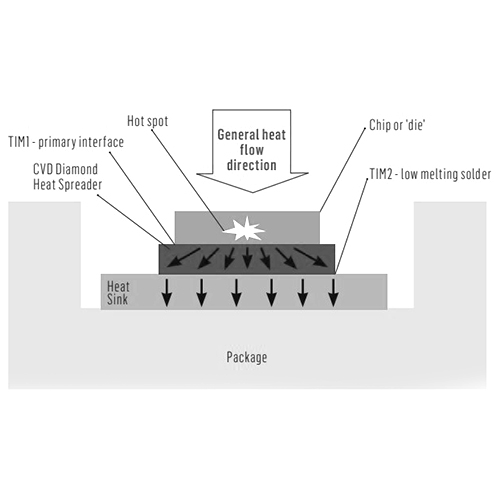

Diamond possesses much better thermal conductivity (2100 W/mK) compared to silicon. This means that diamond can be used to overcome the overheating issues in turn increasing the life team of machines. Using diamonds as semiconductors will help preventing the damages of the operating modules and also improve their working capacity in extreme conditions. For instance, nanodiamonds have already been established as highly efficient in the application of solar energy production owing to their capability of withstanding and redirecting extreme temperatures.

The thermal management properties of CVD diamonds deal with today’s single-largest failure in electronics. This single-largest failure is heat.

- Heat spreaders with 4 levels of thermal conductivity available- 1000-2000 W/mk

- GaN on diamond wafer substrates are offered with 3x improvement in heat dissipation whilst preserving RF performance

- It outperforms silicon carbide, copper and aluminum by factors of 3-10

Heyaru’s proficiency guarantees the ease of customer implementation: Heyaru facilitates the customers to integrate its free-standing diamond heat spreaders into their systems and modules.

- Low roughness and very flat models ensuring the ease of attachment and minimized thermal interface resistances

- Up to 3mm thickness is available

- Metallization solutions enable die bonding with low thermal barrier resistance, consistent with the industry standard brazing and soldering

- Extended device lifetimes for a specific power level with increased efficiency and performance

- Heyaru’s CVD diamond heat spreaders and GaN on diamond wafers.

Thermal Management: Highest room-temperature thermal conductivity of any material. The thermal management properties of CVD diamonds deal with today’s single-largest failure in electronics. This single-largest failure is heat.

- Heat spreaders with 4 levels of thermal conductivity available- 1000-2000 W/mk

- GaN on diamond wafer substrates are offered with 3x improvement in heat dissipation whilst preserving RF performance

- It outperforms silicon carbide, copper and aluminum by factors of 3-10

Heyaru’s proficiency guarantees the ease of customer implementation: Heyaru facilitates the customers to integrate its free standing diamond heat spreaders into their systems and modules.

-

Low roughness and very flat models ensuring the ease of attachment and minimized thermal interface resistances

-

Upto 3mm thickness is available

-

Metallization solutions enable die bonding with low thermal barrier resistance, consistent with the industry standard brazing and soldering

-

Free standing diamond available in large areas upto 140mm diameter that can be laser cut to preferred size

-

Extended device lifetimes for a specific power level with increased efficiency and performance

-

Heyaru’s CVD diamond heat spreaders and GaN on diamond wafers

Extended device lifetimes for a given power level and increased performance and efficiency facilitate the next generation of:

- Optoelectronics Devices

- Semiconductor Assembly and Test Equipment

- High Power RF Devices

- High voltage Power Devices