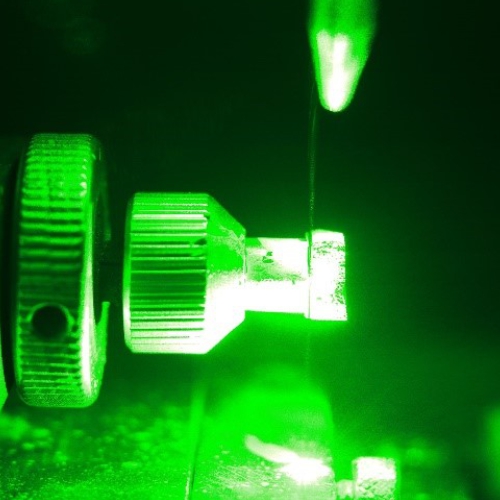

Laser

Most industrial applications of synthetic diamond have long been associated with their hardness; this property makes diamond the ideal material for machine tools and cutting tools. As the hardest known naturally occurring material, diamond can be used to polish, cut, or wear away any material, including other diamonds. Common industrial applications of this ability include diamond-tipped drill bits and saws, and the use of diamond powder as an abrasive. In the production of laser optics where synthetic diamond provides optimum exit windows for CO2 lasers, such as those used in automotive cutting applications.

Diamond has found applications in spectroscopy, high-power radiofrequency generators, long wavelength infrared imaging, disc lasers, Raman lasers and high-power CO2 lasers. Its role in the last of these illustrates why diamond is so valuable.

To make practical use of the output of a high-power CO2 laser (for laser-cutting and the welding of steel), the radiation beam it generates has to be able to escape the chamber in which the lasing gas is confined. It does this through a window at one end of the laser’s casing. If too much of the emerging beam is absorbed while it passes through the window, then overheating can occur which results in the formation of a thermal lens. This strongly affects the beam quality and the position of the laser focus.

Diamond also excels in radiation detection applications where volume sensitivity, radiation hardness and/or temperature insensitivity are required.